Absorption vs. Adsorption in Nitrogen Generators

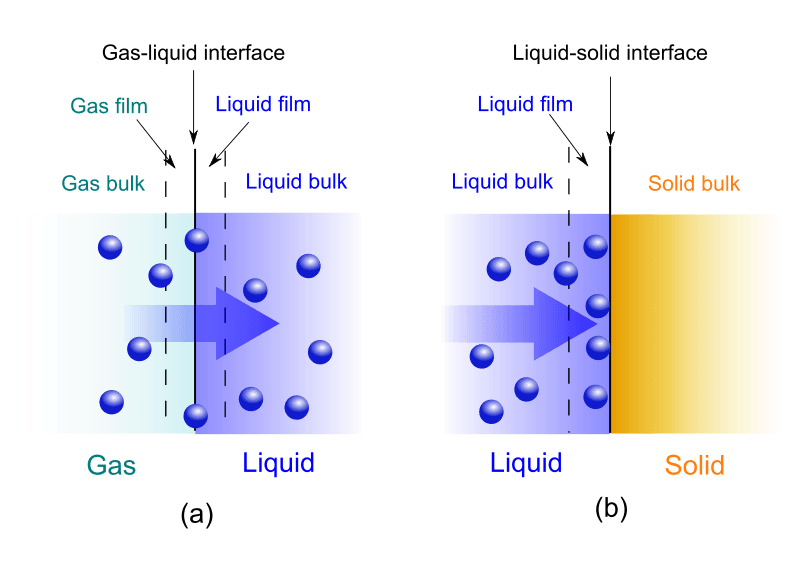

Absorption is the process in which a substance in one state is incorporated into another in a different state. Adsorption is the process of atoms, ions, or molecules adhering to the surface of the adsorbent. When absorption occurs, the molecules dissolve or diffuse into the absorbent and form a single solution with molecules that cannot be separated out from the absorbent. During adsorption, the molecules remain on the surface of the adsorbent and can therefore easily be separated out and removed. When both take place at the same time it is called Sorption.

| Absorption | Adsorption | |

|---|---|---|

| Absorbent/Adsorbent | Bulk | Surface |

| Heat Exchange | Endothermic | Exothermic |

| Temperature | Not impacted by temperature | Favors low temperature |

| Rate of Reaction | Uniform rate | Increases until it reaches equilibrium |

| Concentration | The same throughout the material | Concentration on the surface is different than the bulk |

| Attaining Equilibrium | Comparatively slower | Comparatively faster |

Peak Gas Generation's i-Flow Nitrogen Generator uses Pressure Swing Adsorption (PSA) technology to separate compressed air. Compressed, high quality air is put into the column where oxygen and other gases are adsorbed by the Carbon Molecular Sieve material while nitrogen is allowed to pass through to the application.

Utilizing the latest gas generation technologies, i-Flow is the best in its class of PSA based nitrogen gas generators. It is a highly cost effective, efficient & reliable solution for supplying nitrogen gas to a broad range of manufacturing and processing applications, such as blanketing, drying, food processing, and many more.

A single i-Flow generator can produce over 4000 liters per minute (7,212 SCFH) of clean, dry nitrogen gas, at purities ranging from 5% to 99.9995% (ultra-high purity N2). Instead of needing to purchase a new system or needing to increase the frequency of your cylinder deliveries if your demand increases, more columns can be added to your i-Flow system, which makes it future-proof. i-Flow is not only capable of meeting broad and varying customer supply requirements, it can also help companies improve manufacturing efficiencies, reduce costs and meet environmental sustainability targets.

A. Absorption vs. B. Adsorption

What caused the CO2 shortage and how can you protect your supply chain in future?

Posted in all news on July 13 2018With CO2 being used extensively in the food and beverage industry there is a good chance that…

Read MorePeak Gas Generation to exhibit at FABTECH in November 2018

Posted in all events on August 06 2018About FABTECH: FABTECH is North America’s largest metal forming, fabricating, welding, and…

Read MoreSavings Calculator

Majority of industries buy nitrogen gas supplies via nitrogen cylinder packs, others meet their needs through liquid nitrogen dewars, micro-bulk tanks or bulk liquid nitrogen delivery. There is a better, more sustainable & safer option. Reduce the cost of nitrogen gas to your organisation & become self-sufficient. Find out how much you can save with a Peak nitrogen generator system.

- liquid/bottled N2Cost of liquid/bottled N2

- InvestmentInvestment cost

- TransportTransport cost

- ServiceService cost

- LeaseLease equipment

- EnvironmentalEnvironmental Tax

- EnergyEnergy cost